FX7 How is Coal Formed?

Some theories say that coal is made from the accumulation of peat in ancient swamps. Others have observed that coal seams found in the Midwest are formed from nothing but tree bark and point to what is now happening at Mount St. Helens in Spirit Lake. This explanation is referred to as the Floating Log Mat theory and suggests that large floating mats of trees have rubbed together and dropped all their bark in one location. This layer of bark was then covered with hundreds or thousands of feet of sediment to provide the pressure and heat to transform the bark into coal. Experiment FX7 is our first attempt to test this theory that bark can be turned into coal.

First we took bark from a dead tree and cut it into small pieces to ensure a uniform symmetric pressure in our reaction vessel. We then soaked it in a mixture of water, clay, iron powder and sulfur, all said to be found in coal. Interesting to note is the sulfur reacted with the iron to turn the whole mixture coal black.

We then compressed and heated the bark pieces to 1500 psi compression to simulate the sedimentary overburden, added 800psi water pressure to simulate the vertical head pressure of the water table and prevent boiling it dry, and heated to 480F to simulate the geothermal energy required to transform the bark to coal. It is important to note that these numbers are our best guesses since actual measurements are not available. At best they are estimates based on observations.

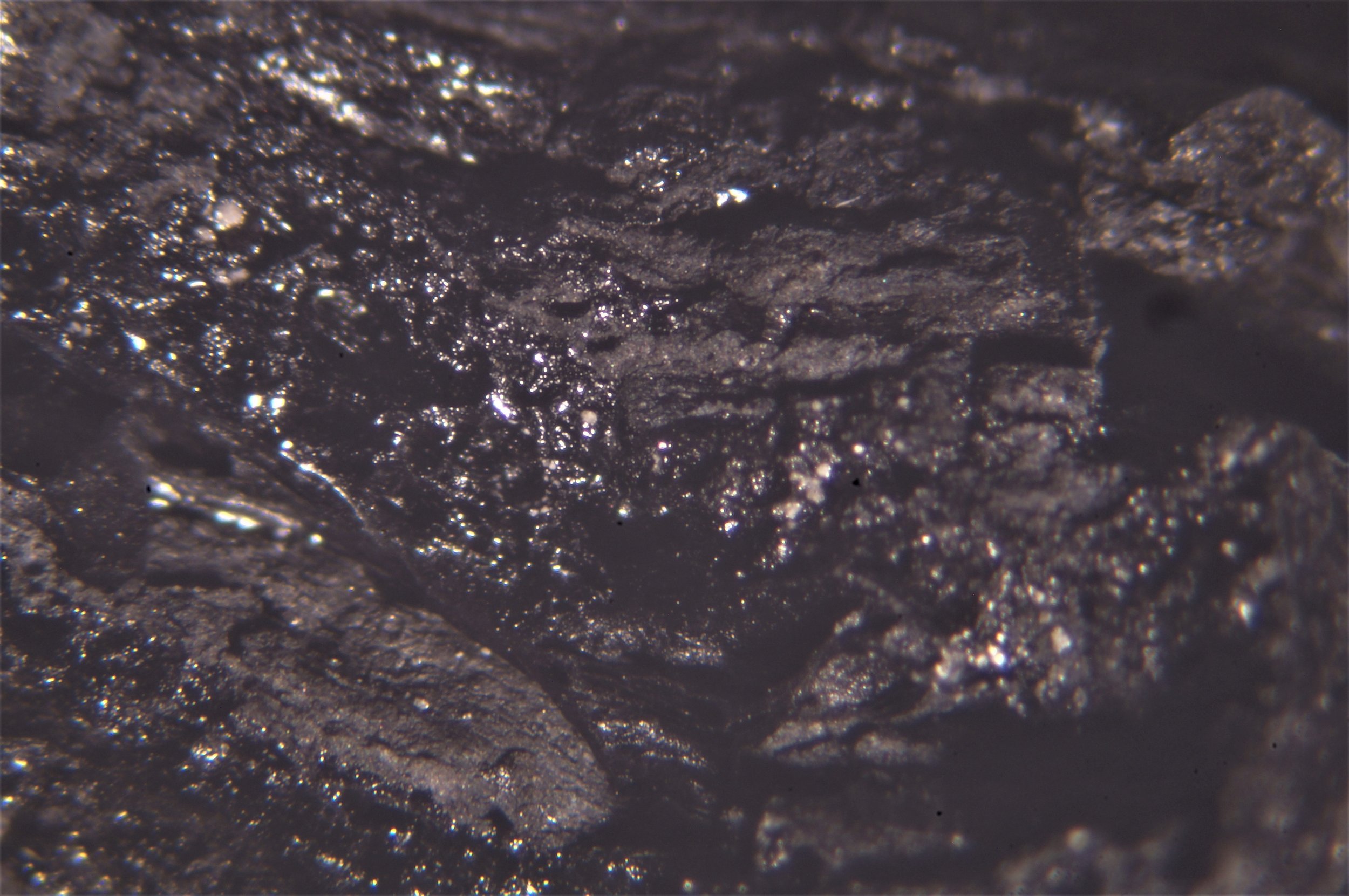

At first the coal came out of the reaction vessel as a hard solid block. The block was still wet since I let the whole sample cool without venting the steam. The water was re-absorbed and caused the block to de-laminate into individual pieces of bark that looks very much like small chunks of coal. Breaking these small pieces and looking under a microscope, it was observed that the broken edges were bright and shiny very similar to my samples of Bituminous coal. However when you look more closely you will notice that the small bark pieces are very porous and the bituminous coal in the pictures below is not. The porosity can be explained by the fact that the sample compressed far more than anticipated and the hydraulic ram was fully extended. So even though the hydraulic pressure indicated 20,000 lbf, there is is no way to know what the final pressure on the sample actually was. The final reduction in volume was over 85% by volume and would have been more had the ram not reached it’s limit.